Semi-autogenous (SAG) mill liner

I. Application

Same as the ball mill liners, the semi-autogenous mill lining plates are all used to protect the mill's body from the direct impact and wear of grinding ball and materials. At the same time, the different shapes of the lining plate are used to adjust the movement state of the mineral, thereby enhancing the efficiency of grinding and crushing. which is helpful to improve the grinding efficiency, increase the output and reduce the metal consumption. But the semi-autogenous mill lining plate has unique characteristics, because the semi-autogenous mills are with larger diameter, larger grain size, low filling ratio of steel balls, the ore itself needs to act as part of the grinding media, which requires semi-autogenous mill lining plate to have certain degree of hardness to resist grind ball fatigue wear, this also need to resist cutting wear from edges and corners of the ore. Due to the larger diameter of the semi-autogenous mill, it required to reach a sufficient impact and toughness value , so as to avoid deformation and fracture failure. Therefore, the design needs higher requirements.

II. Application status in the international and domestic markets

CITIC HIC, Metso, NHIC, Rongmao Steel, Me-elecmetal etc.

III. Property and advantages

1.High wear and impact resistance

With scientific and reasonable formulation of alloy elements, the semi-autogenous mill lining plate has good physical and chemical properties. So it can withstand high impact, produce hardened layer around the alloy surface constantly during the application, and improve the wear resistance.

- High strength, high toughness

By using the special quenching medium agent with thermal stability in the quenching process, Semi-autogenous mill lining plate combine high

strength, high hardness and high toughness perfectly, since greatly improve the impact toughness, so can be used in semi-autogenous mill has a

larger diameter, satisfy high impact and wear resistance technological requirements

3. High cost-effective, strong adaptability

Through the independent designed heat treatment process of our company, semi-autogenous mill lining plate has a unique feature with quenching, combine high hardness and high toughness. So that the product not only has good wear resistance and high impact load resistance, but also improves the grinding efficiency and increases the machine-hour capacity.

IV. Using effect contract

(Used in Φ8.8m SAG mill of China Gold Inner Mongolia Mining Co.,Ltd)

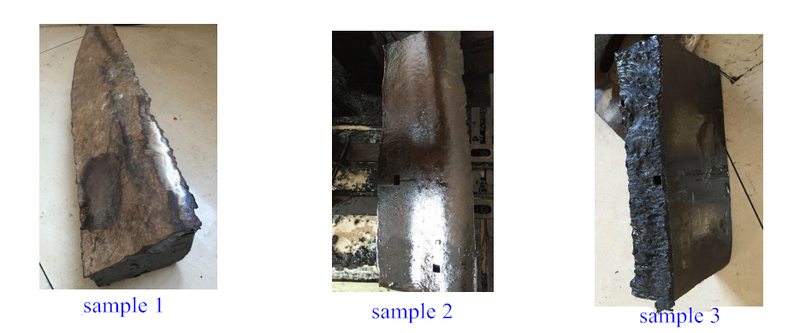

Our new lining plates

The used liners of other suppliers

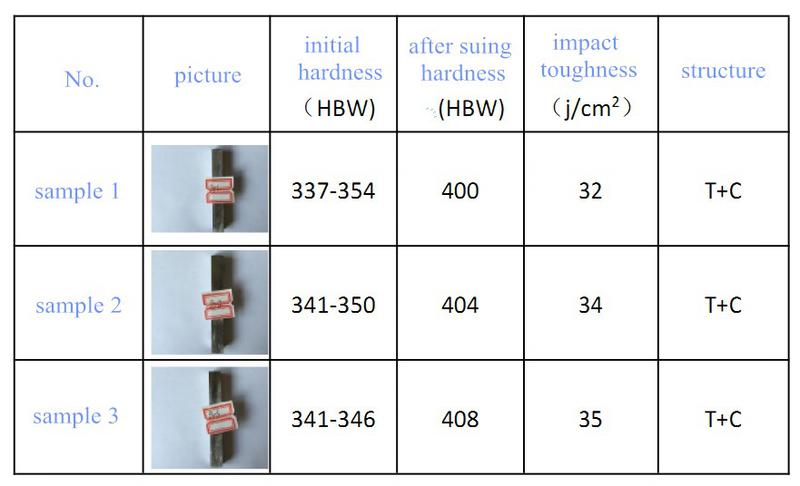

V. Sampling and testing

Other suppliers’ products:

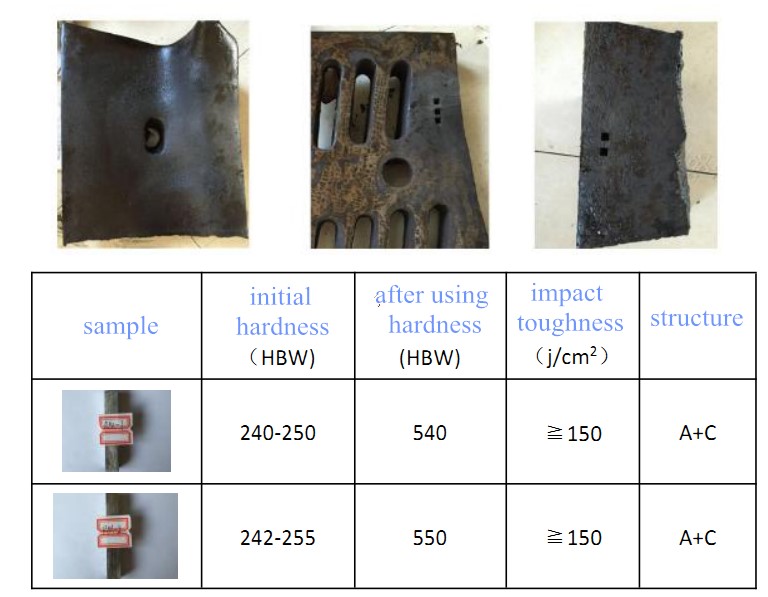

Our products:

Comparison of Cr-Mo Alloy liners and Our Alloy Liners

|

Type |

Initial hardness |

After using hardness |

Impact toughness(j/cm2) |

Micro structure |

|

(HBW) |

(HBW) |

|||

|

Cr-Mo Alloy liners (other supplier) |

345 |

404 |

33.5 |

T+C |

|

Alloy Liners (our company) |

350 |

540 |

≥150 |

A+C |

Multielement Alloy SAG Mill Liners' Property and Advantages

Our company cooperated with some famous universities,form a scientific research team with experts and scholars, use advantage production equipment. With our many years' research on many mines' mill liners and rich experience in design , we invent multielement alloy liners, which combined hardness and impact toughness perfectly, so it is not easy broken, with long using life. This type liner is suitable for SAG mills with size not less Φ5m,our liners can satisfy with the high requirements by using our special heat processing, the impact toughness can be 120-150J/cm², hardness can be HRC52-58, the properties reached the international advanced level, but the price is lower more than 20% than Cr-Mo alloy lines.

Our company strictly comply with the ISO9001quality management system to assure high quality, to satisfy customers' requirements and improve economical efficiency.

Through our customers' application and verification, our SAG mill liners are without deformation and fracture, excellent wear resistance, reduce the production cost, improve efficiency,with good cost performance, greatly satisfy the metallurgical mining and mineral processing and other production enterprises, are ideal alternative products to traditional low/medium/ high carbon Cr-Mo alloy liners.