Quality Control

Quality Control

With the company's R & D center as the core, we adopt a combination of independent research and development and open research and development, and work closely with many domestic universities and research institutes. The use of the latest research results and the latest domestic advanced technical means to produce the most cutting-edge products in the casting industry. Science and technology leads to fashion, science and technology creates wealth.

Quality Control

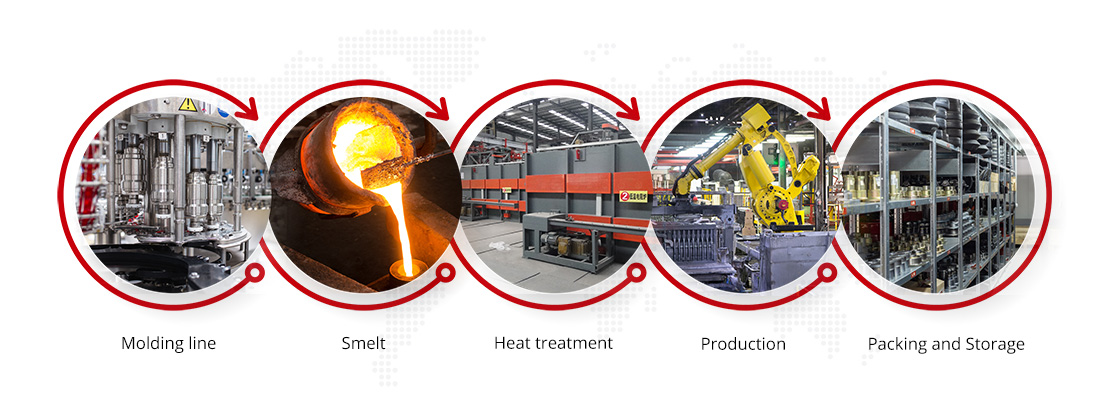

- Raw Material: choose high quality edge materials from steel mills and high quality cold pressed plates from automobile manufacturers to press the briquettes.

- Modeling: adopt iron mould covering sand process to improve the appearance quality and inner toughness of the product.

- Formula of Furnace Charge: through computer sampling test to reach product qualified ratio, production can continue.

- Melting and Pouring: Adopt advanced American Inda intermediate frequency furnace, chemical composition for quality inspection before furnace, to achieve melting ratio needs. The pouring machine is controlled by computer imported from USA, and the bottom method of pouring is implemented to improve the quality of iron, which must be finished within the effective time. If not, it will be returned to the furnace for new melting ratio until qualified.

- Sand Clearing: Set a certain time to separate the semi-finished products from the sand clearing process.

- Heat Treatment: Adopt self-developed heat treatment process, with fully automated computer programming control, using isothermal heat treatment, the secondary stress relief.

- Substandard Products and Waste Products: In the whole stress treatment process, any substandard products and waste products will be returned to the raw material.

- Finished Products: We use six quality control processes to eliminate the secondary stress and finally reach qualified products.

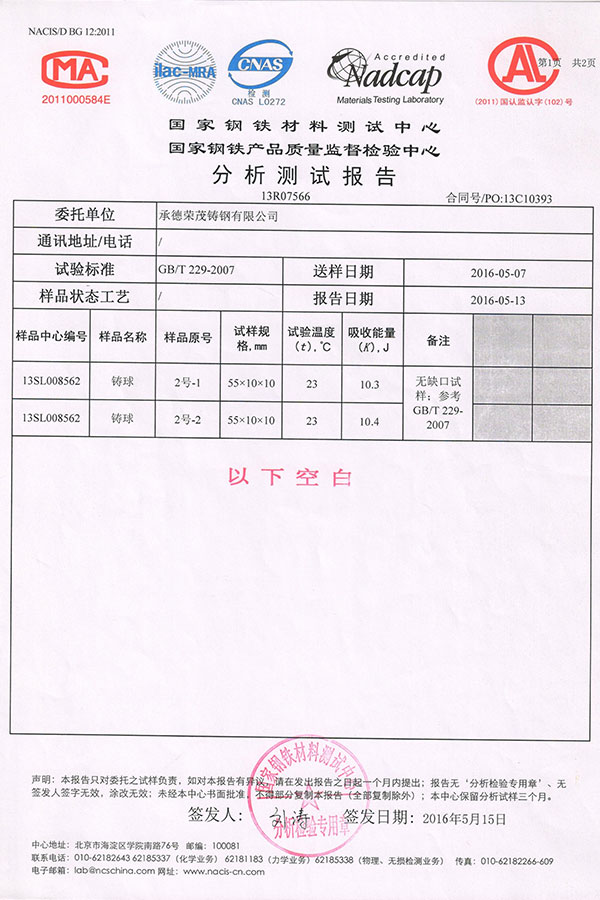

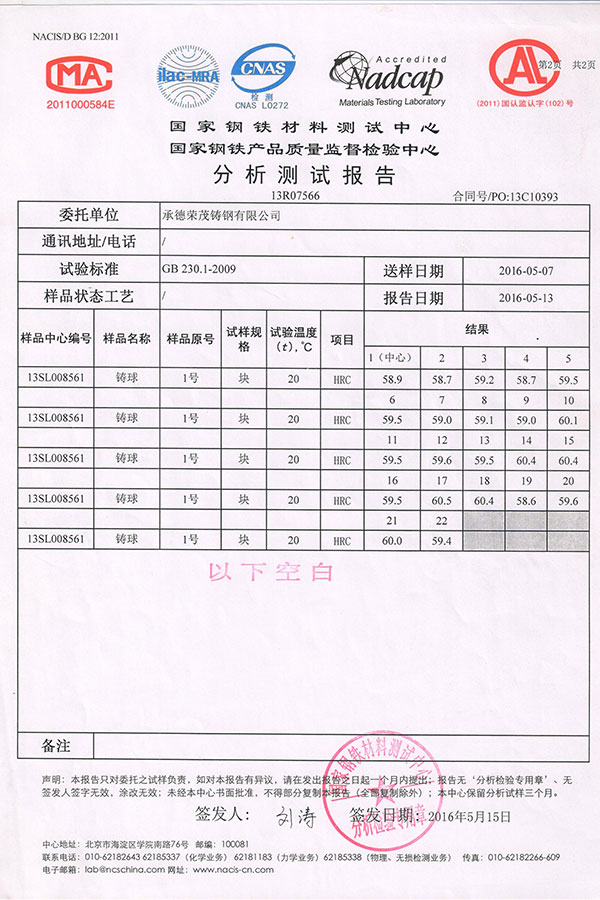

Related Testing Equipment

- WEDM

- Pendulum impact tester

- Rockwell hardness tester

- Energy dispersive X-ray fluorescence spectrometer

- Benchtop direct reading light meter

- Carbon and sulfur analyzer

- Non-contact temperature measurement

- Hardness blocks on the Leebster

- inverted metallurgical microscope

- Universal testing machine

- Impact testers

- Collared Optical Microscope

- scanning electron microscope

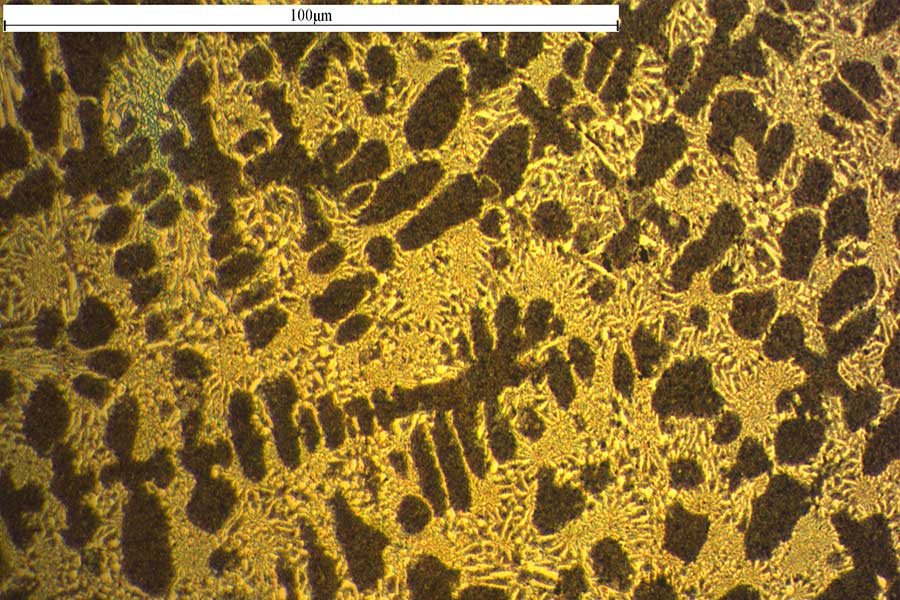

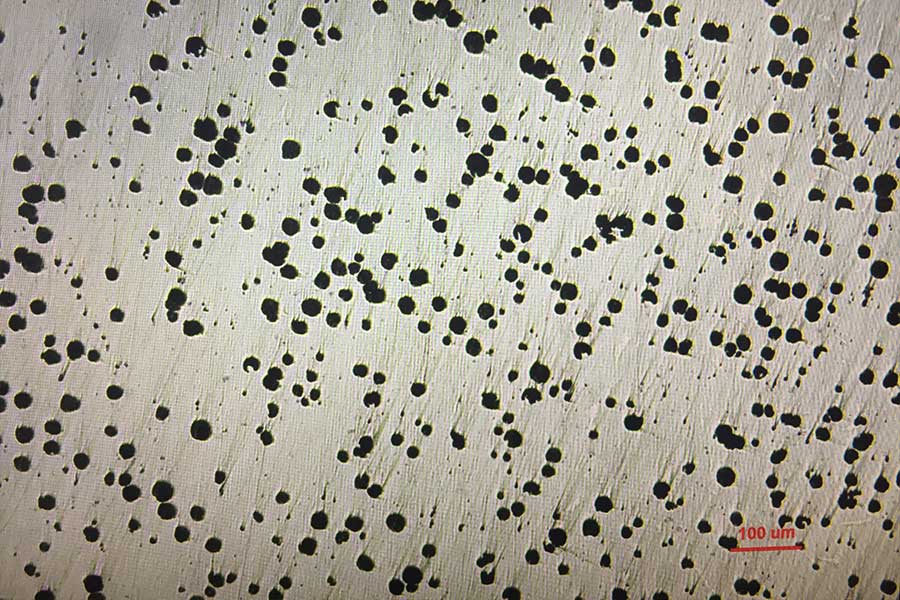

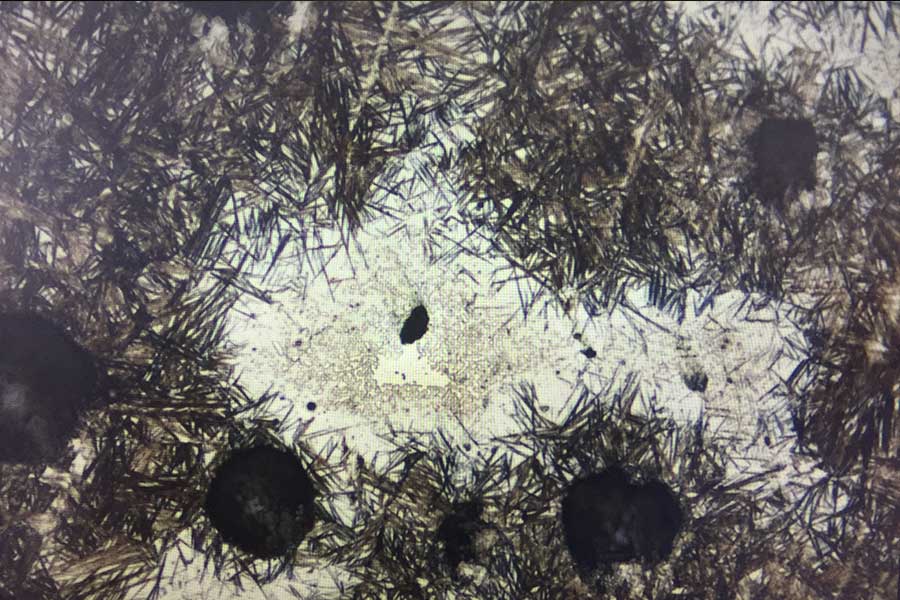

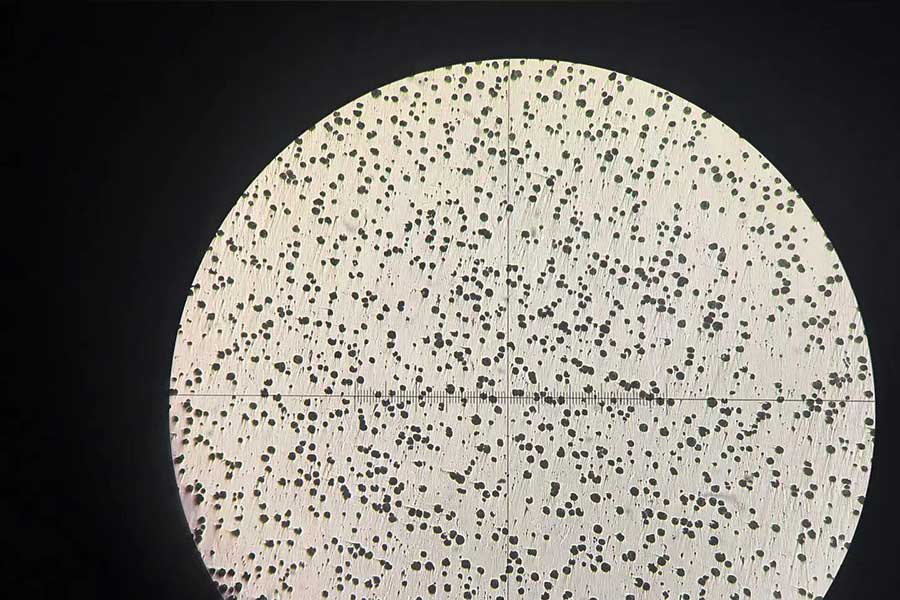

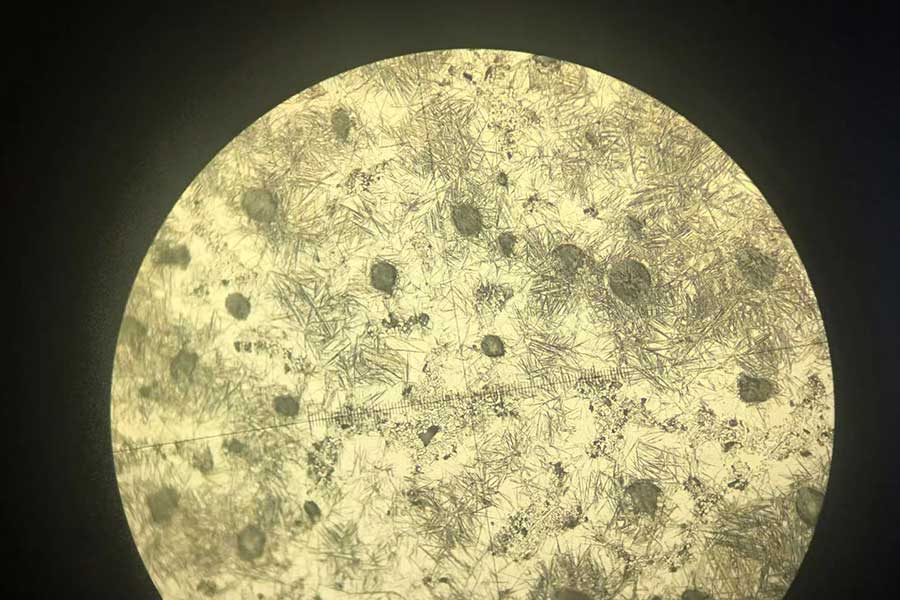

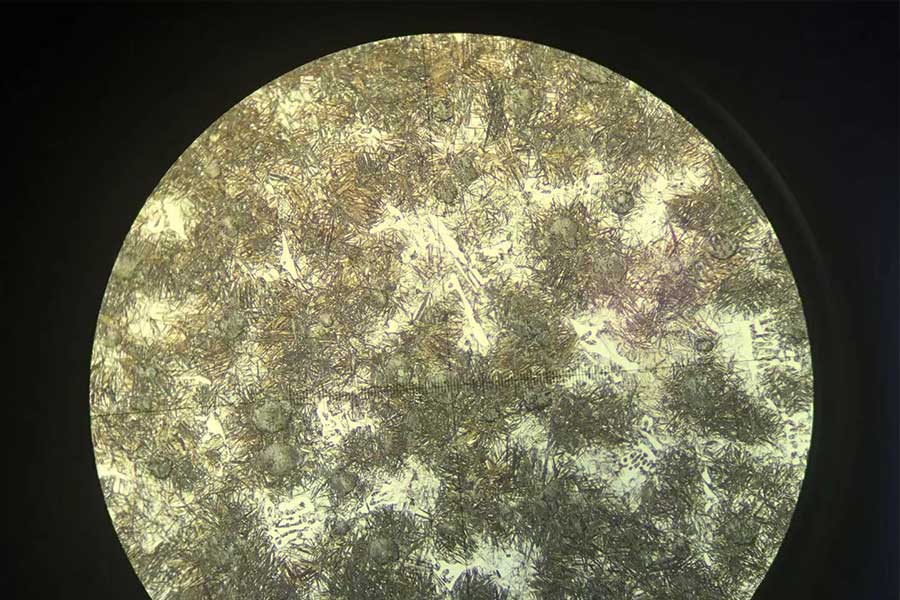

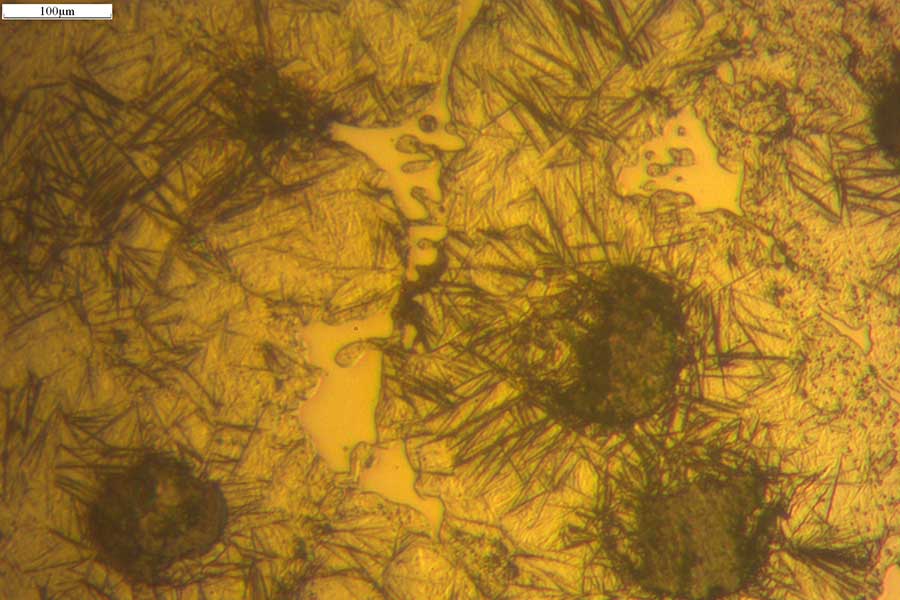

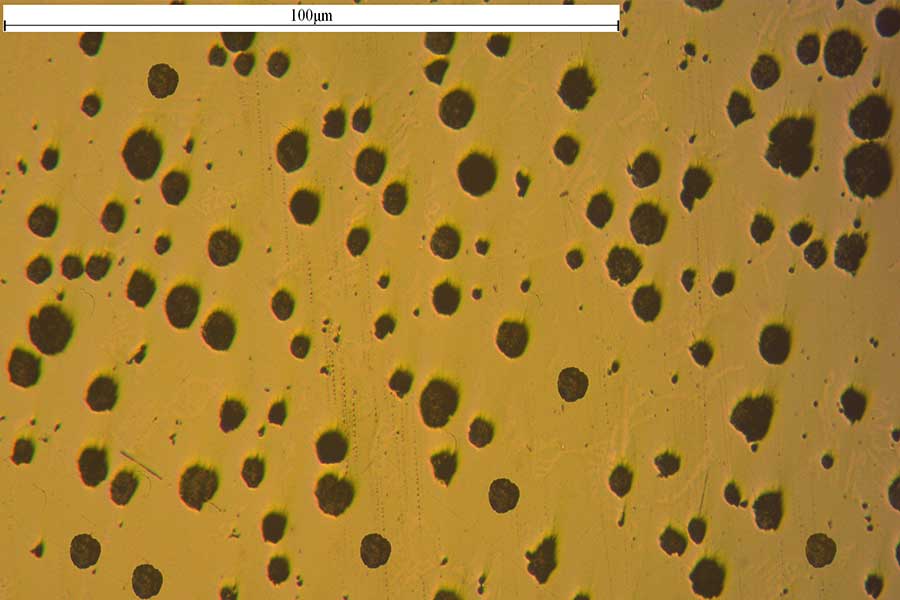

CADI Grinding Ball Metallographic Structure

Corporate Documents

Standardization of Production Safety

Certificate of Scientific and Technical Achievements (Municipal Level)

Enterprise Credit AAA

Unit Responsible

Hebei Science and Technology-based SMEs

Certificate of Transformation of Major Scientific and Technological Achievements in Hebei Province

Certificate of Scientific and Technical Achievement

Famous Trademark Certificate

Science and Technology Progress Award (county level)

Science and Technology Progress Award Certificate

Brand Companies

Provincial Leading Enterprises

National High-tech Enterprises

Advanced Units (County Level)

Advanced Units

Advanced Units

Excellent Service Provider

Small and Medium-sized Enterprise Brand Products

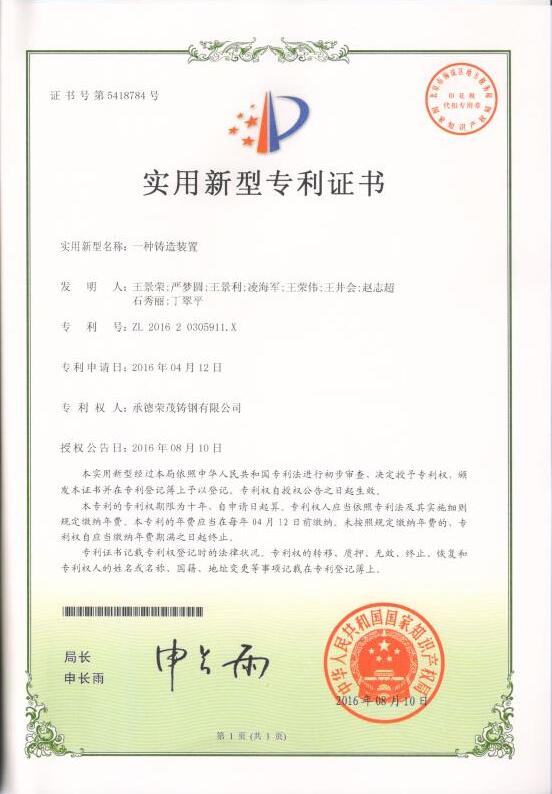

Patent Certificate