Laboratory

Our Laboratory

The New Ausferrite Ductile Iron Technology Engineering Laboratory is jointly built up relying on Chengde Rongmao Cast Steel Co., Ltd. together with Hebei University of Technology. Chengde Rongmao Cast Steel Co., Ltd. has many years experience in ausferrite ductile iron production and product R&D, both product quality and production technology reach domestic advanced level. Its products have been sold to major domestic large-scale mining enterprises and many countries and regions in Asia and Europe, with high prestige at home and abroad. The Energy Equipment Materials Technology Research Institute R & D team of Hebei University of Technology, consisting of leading talents including distinguished experts and professor from the Thousand Talents Plan, Changjiang Scholar, with consistent platform support from "high-quality metal structure materials R & D team" of giant plan innovation team in Hebei Province and the international advanced level of analysis and testing Research. In 2015, the two sides jointly applied for the construction of laboratory and later constructed after verify and approval of Reform Commission.

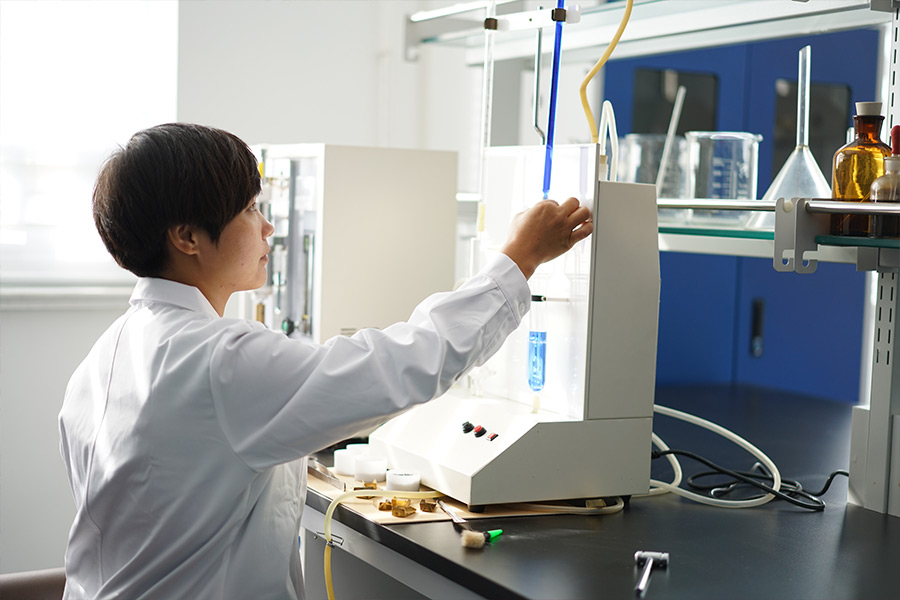

The laboratory found a technical committee responsible for setting laboratory development planning and laboratory construction goals so as to provide technical support for laboratory development. It consists of product R&D department, service performance evaluation center, casting technology research room, heat treatment technology research room and equipment research department and other R & D department, and has initially formed a professional and age mutually matched high-quality R & D team. Current research staff is 37, of which 9 are senior staff, 15 are senior engineers, with 16 bachelors.

The laboratory has a total investment of 1700 million yuan, the construction area covers more than 1,300 square meters. It has been equipped with scanning electronic microscope, metallographic microscope, spectrum detector, universal testing machine, wear resistance test machine, smelting equipment and 148 sets of heat treatment R&D equipment. The built mechanical properties testing room, microstructure analysis room, physical and chemical analysis room and other laboratories have commonly contributed to forming an entire analysis system.

Inspection Process

Sampling

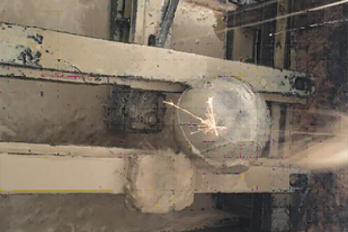

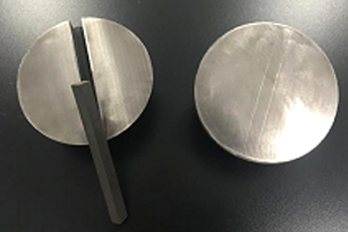

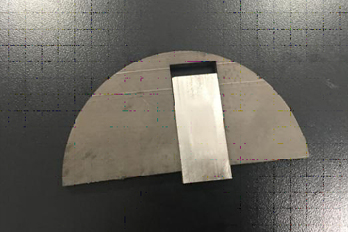

Choosing the sample ball from the whole batch of grinding balls at random, then machining it into test block by WEDM for further testing its impact value, hardness, microstructure, wear resistance.Operation as shown below:

Choose Sample Ball

Sample Machining

Specimen for Strength & Microstructure Test

Test Specimen for Wear Resistance

Testing Sample Impact Toughness

The impact value of the test specimen (10*10*55) is measured according to the GB 229-1994 Metal Charpy impact test method. Test equipment as shown below:

Automatic low-temperature impact testing machine is one kind of impact tests machine designed to measure the resistance to failure of a material to a suddenly applied force. Meanwhile testing the impact toughness of these materials in low temperature environment.

Testing Sample’s Core and Surface Hardness

Sample ball hardness is tested.according to the GB 230.1-2004 metal hardness test method, test equipment as shown below:

Rockwell Hardness Tester

Brinell Hardness Tester

Vickers Hardness Tester

HL Hardness Tester

Testing Specimen Metallurgical Structure

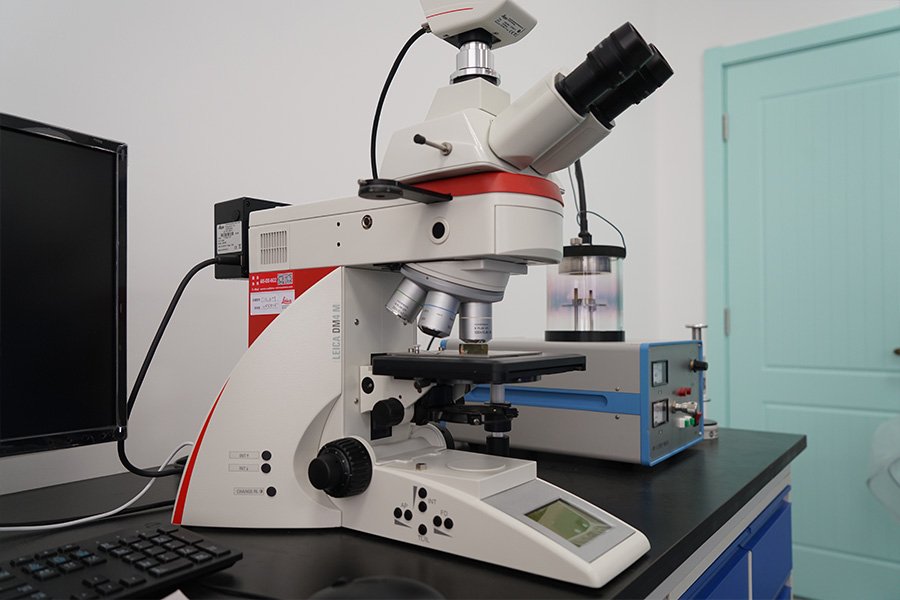

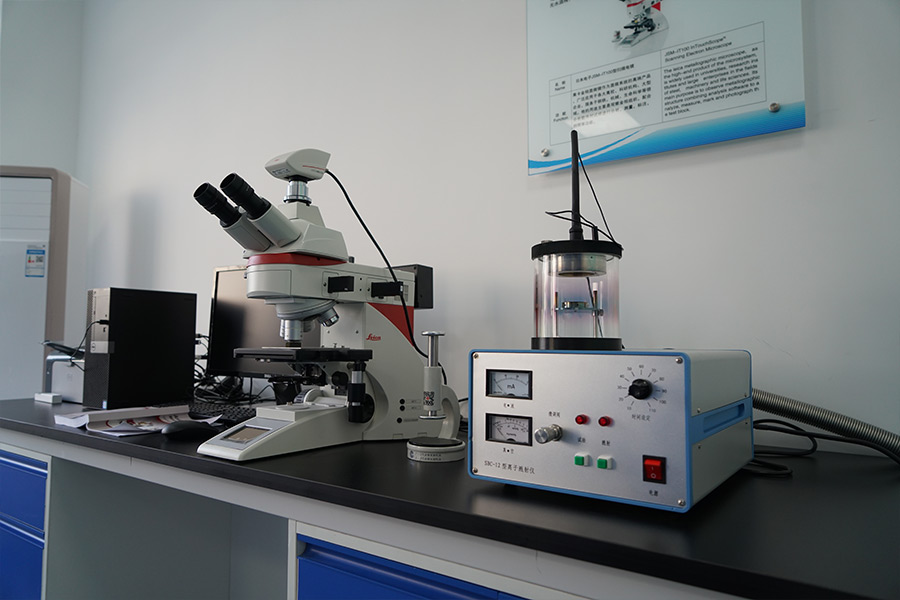

Test specimen’s microstructure is tested.according to the according to the metallographic standard GB/T1.1---2009, test equipment as shown below:

Microscopes Leica DM4

Scanning Electron Microscope

Testing Specimen Wear Resistance Property

The wear resistance of the test specimens was measured by abrasion test on the test machine with a sample.Test equipment as shown below:

Dry &Wet Sand Rubber Wheel Test

Dynamic Abrasive Wear Test

Organize and Collect the Test Data into Files.

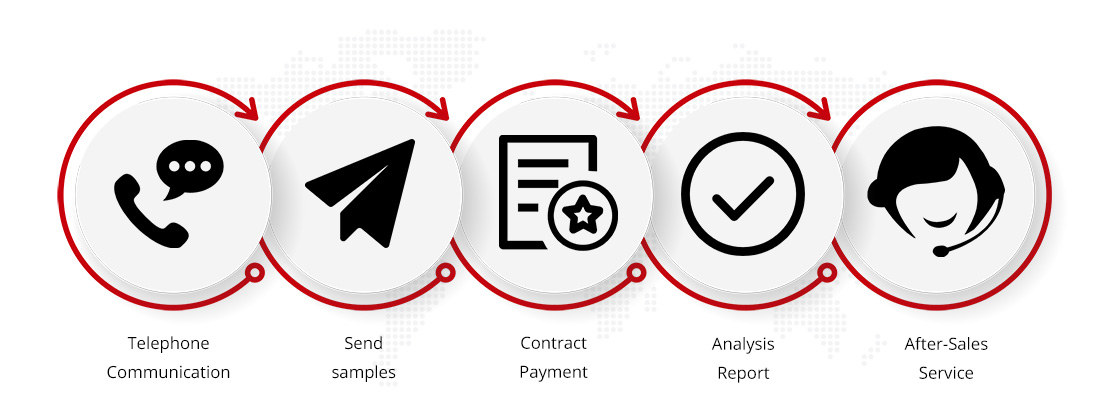

Cooperation Process